product

Location: Home > product > Laser welding machine > Laser mold welding machine

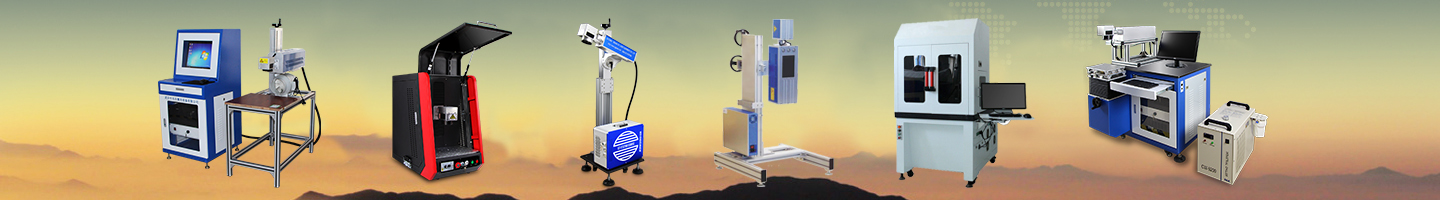

Laser mold welding machine

IntroductionModelOrder Online Demo Show

Yag Laser Welder Series

Model introduction

The laser deposition welding system (laser mould welder) is specially designed for the mould industry and used in repairing of precision moulds, such as mould manufacture for digital products, mobile phone, toy, automobile and motorcycle, and molding industry. Through the repairing of moulds, it is possible to reuse the moulds, save the production cost and improve the working efficiency significantly. This technology can also be used to modify the design or size of moulds to reduce the development period.

Model Features

The working principle of this laser deposition welding system is to use laser high thermal energy and the melting technology in spot to process the welding and repairing of minute parts. It makes up the shortage of traditional hydrogen arc welding in repairing precision surfaces, avoids the two difficulties of thermal strain and after-treatment, and saves the production period of mould.

The main advantage

Tailored specifically for the mold industry, the introduction of German technology, unique design, suitable for a yariety of large, medium and small patches of mold.

The British imported ceramic condenser cavity, corrosion resistance, high temperature, cavity lifetime (8-10), the xenon lamp life of more than 8 million times.

The world's most advanced automatic shading system, eliminating the time at work to stimulate the eyes.

Laser head can be rotated 360 degrees, the overall optical path part can rotate 360 degrees, as well as up and down electric lift, push around, especially for a variety of large, medium and small patches of mold.

Parameter adjustment with intelligent remote control,simple operation and fast.

Electric lift table can be three-dimensional movement.

Electrically adjustable spot size.

Application areas

The materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, high grade steel, steel alloy, high tenacity aluminum alloy, etc.

>>>Technical parameters:

Model GGHJ-M300

3-axis stroke of work bench X=300mm, Y=200mm

(X,Y can be adjusted manually and Z-axis can be lifted)

Bearing of work bench ≤ 200KG

Device weight 300kg

Power supply 220V±10%/50Hz or 380V±10%/50Hz

Laser parameters

Laser type Nd:YAG pulse

Laser wavelength 1064nm

Max single pwls energy 40J

Pulse width 0.2〜20ms

Maximum laser power 180W/200W

Pulse frequency 1〜15Hz(Adjustable)

Light point 0.3〜3.0mm(Adjustable)

Laser cooling Water cooling

Protection gas 1 channel (argon)

Solder parameters

Welding wire diameter 0.1mm〜0.6mm

Address:Wuhan Optical Valley in laser equipment Ltd.

switchboard: 86-27-87207888 Extension;86-27-87207888Turn8188 8288

Marketing Center: 86-27-83566512 83566502 83566517 13707157835

Navigation | Disclaimer | china•ov Wuhan OV Future Laser Equipments Co.,Ltd.All rights reserved 553366